Batch Ovens

LEWCO’s line of Industrial Batch Ovens set the industry standard for efficient process heating.

Drum and Tote Heaters

LEWCO is the world leader in the designing and manufacturing of Drum Ovens, Tote Ovens, Drum Hot Boxes, Tote Hot Boxes and Drum Heating Tunnels.

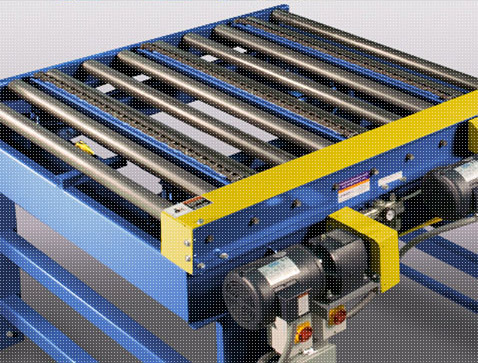

Conveyor Ovens

LEWCO is the ONLY U.S. based Industrial Oven manufacturer that also manufactures a standard line of conveyor products.

Learn More

Lewco, Inc designs and manufacturers industrial ovens for a wide range of applications. Our product line includes composite curing ovens, drying ovens, paint baking ovens, annealing ovens, walk-in batch ovens, conveyor ovens, drum ovens, tote ovens, heating tunnels, labratory ovens, and more.